Gear Products

We have comprehensive manufacturing facilities that enable us to manufacture transmission gears for a whole raft of industrial applications. The types of gears we manufacture include spur gears, helical gears, sprockets, racks & pinions, worm shafts and pulleys. For more information please call 01279 425358.

Spur Gears/Straight Cut Gears

Spur gears are one of the most common types of gear. The gear teeth are straight and can be used to change rotational speed from one shaft to another and/or rotational direction and can offer large gear reductions. Spur gears are generally manufactured either by gear hobbing or gear shaping. Due to their design, spur gears are known as slow speed gears and are noisier than helical type gears. B&F can provide spur gears from 5mm up to 1220mm in diameter and the pitch ranges from 100 DP to 2 DP (0.254 MOD to 12.7 MOD). Spur gears can be finish cut, ground or even shaved.

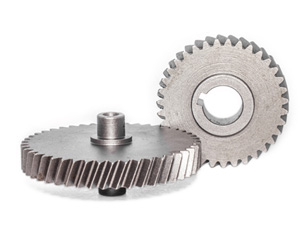

Helical Gears

Helical gears are a good choice if noise is a critical issue. Angled teeth engage more gradually than a spur gear, causing them to run more smoothly and quietly. They are also used if an application involves high speed and large power transmission.

B&F can produce helical gears from 5mm to 1220mm in diameter and the pitch ranges from 100DP to 2DP (0.254MOD to 12.7MOD). Helical gears can be finish cut, ground or even shaved – we have capacity for all of these finishes.

Sprockets

A sprocket is a wheel that meshes with a chain or track; sprockets never mesh together directly. Simplex, duplex and triplex sprockets can be produced to suit ANSI or BS chain ranging from 5mm up to 3” pitch. These can be manufactured in various materials including stainless steel and acetal. Taper lock and nonstandard bores can be catered for along with keyways, grub screw locking and nonstandard numbers of teeth. Max diameter 1220mm, max face 381mm, max pitch 25.4mm.

Pulleys

Pulleys are used in a variety of ways to lift loads and to transmit power. B&F can produce a wide range of timing pulleys of various pitch and width. Pulleys can be manufactured with or without flanges to suit customers’ individual requirements. Special requirements such as nonstandard bores, keyways and special machined features can be accommodated.

Gearbox & Assemblies

Straight or right angle gearboxes can be produced, either worm drive or spur, foot or shaft mounted. Reduction or straight ratio can be manufactured to suit customers’ individual applications. B&F have a wealth of experience in working with customers on R&D programmes involving a diverse range of gear box requirements.

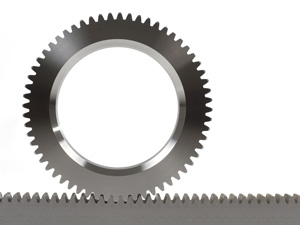

Rack & Pinions

A rack and pinion would be used if linear motion is required. The pinion engages with the teeth on a linear gear or ‘rack’ and this rotational movement causes the rack to move. B&F can provide racks with a maximum face width of 2.5”/64mm and a maximum pitch of 4DP/6.4MOD. The length of the rack that B&F can cut would depend on a combination of face width and the overall cross section of the rack.

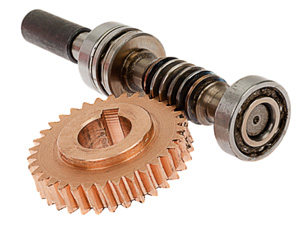

Worms and Wheels

A worm drive is a gear arrangement in which a worm, a gear in the form of a screw, mates with a worm gear, smaller in appearance than a spur gear and also called a worm wheel. Like other gear arrangements, a worm drive can reduce rotational speed or enable higher torque to be transmitted. A gearbox designed using a worm and worm-wheel will be considerably smaller than one made from plain spur gears and has its drive axes at 90° to each other. B&F can manufacture worm wheels with a maximum diameter of 1220mm and worms with a maximum diameter of 230mm. Maximum pitch is 10MOD.

Hubs

B&F manufacture hubs in a variety of sizes and materials, these can be drilled and tapped and can also be ground to suit customers individual requirements.

Hubs can be used in a variety of ways. They are often used in assemblies and can be manufactured in a number of different materials. B&F manufacture hubs in a variety of sizes and materials, some are drilled and tapped and can also be ground if required.

Drive Shafts

A drive shaft transmits torque and rotation and usually connects components in a drive train. Cars use a shaft to deliver power from a differential or transmission to the wheels.

B&F manufacture splined drive shafts in a variety of materials that can be hardened and often powder-coated. Many of these are manufactured for the vintage or classic vehicles restoration industry and so supplied in small and larger batch quantities.