Our gear manufacturing unit comprises a comprehensive range of machine tools housed within our 1672 sq m factory. Along with manufacturing gears complete, we also carry out gear cutting, gear grinding and/or gear shaving on free issue components.

Total Quality Assurance

We are proud of our heritage dating back to 1851 and look forward to securing new business for the future. We can only achieve this by offering our customers high quality products that stand the test of time, ensuring our reputation as a quality supplier and the reputations of our customers.

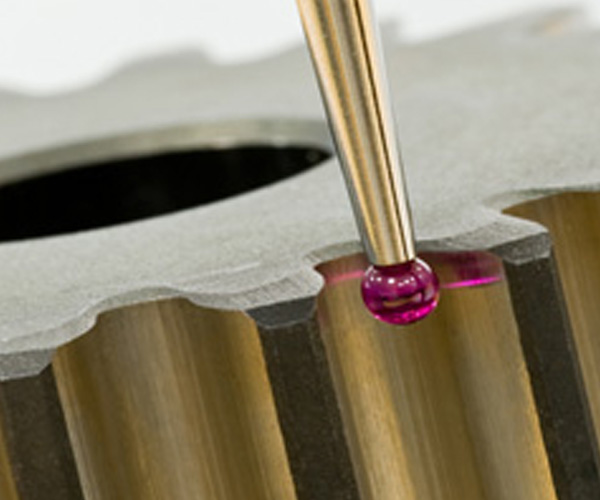

All of the parts we manufacture undergo complete quality assurance checks. We pride ourselves in supplying our customers with a finished product of the highest quality. Each of our manufacturing processes is checked before moving on to the next operation, and a final quality check of items is made prior to dispatch. We have standard QA information that is sent with the goods, however should you have any specific needs regarding the levels of quality control that you require, please get in touch to discuss your requirements.

Free Issue Parts

In addition to manufacturing complete components, we also offer a service where we can finish machine parts from free issue material or blanks. We can either gear cut only and return to the customer to finish off parts, or finish all required machining operations in house.

Gear cutting and deburring only can normally be turned around quickly. B&F can gear cut, and then shave or grind gear teeth if this is required, and can also offer a gear grinding or shaving service to other gear manufacturers.

Manufacture to Drawing

Gears can be produced in a wide range of materials starting from a customer’s drawing going through all manufacturing stages, including heat treatment, grinding, plating , etching and full quality control inspection to the finished product.

Reverse Engineering

Where no engineered drawing exists, B&F are equipped to produce products from submitted samples. Full-engineered drawings are produced from essential information gained from the customer followed by rigorous measurements and calculations enabling a like-for-like product to be manufactured.