History

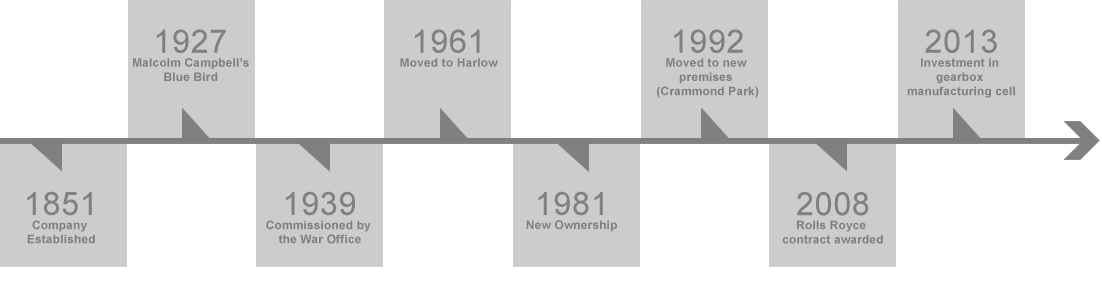

Beard and Fitch Ltd was established in Clerkenwell, London in 1851. Until 1914 the company manufactured clock gears, but the First World War changed the emphasis to heavier and industrial gearing.

Between the wars the company had the prestige of manufacturing the entire transmission for Malcolm Campbell’s world record breaking car, Blue Bird, which in 1927 and 1928 achieved new world land speed records.

In the Second World War, B&F manufactured solely for the War Office, manufacturing gears for armaments of all descriptions but in particular the manufacture of gears for torpedoes. After the Second World War, the company reverted to supplying industrial applications and continued to prosper and invest in new machines to keep pace with contemporary technological advances.

In 1961 the company and most of its employees moved to Harlow in Essex. At the time, a job in Harlow ensured new housing for the employees under the New Towns Commission. In 1967 the competitive edge disappeared, labour was becoming too expensive, the plant was out of date and then when the 1979 recession came, B&F just could not compete.

On 13th April 1981, Acral Gears Ltd, owned by the Archer family, purchased B&F’s total shareholding. A strategic investment plan was implemented to update not only the plant but also, and more importantly, the working practices. By 1994 the company had need for a more modern facility and funding was made available for the move to the current 18000 sq ft (1672 sq m) factory. B&F has since developed into more diverse market sectors.

The company employs over 40 staff encompassing the full manufacturing processes from raw material to the finished product. B&F services include manufacturing to drawing, and reverse engineering from customer samples to part machining free issued components. We provide full inspection and advice and back all our products up with total quality assurance systems. B&F follow a continuous investment programme, with more planned over the coming years.

More about: